Gear Production

Issue link: http://gear.epubxp.com/i/262216

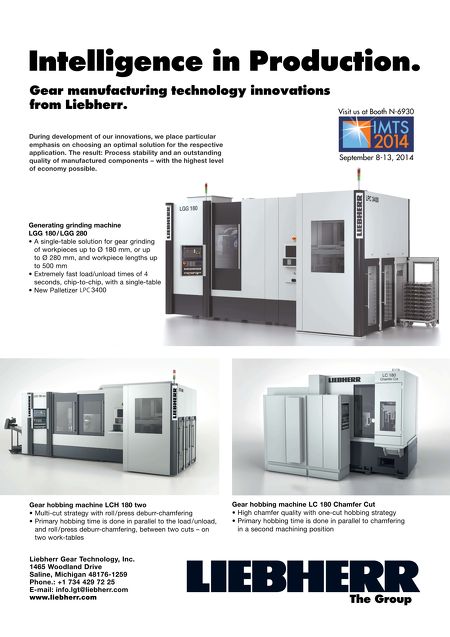

Intelligence in Production. Gear manufacturing technology innovations from Liebherr. Gear hobbing machine LCH 180 two r Multi-cut strategy with roll /press deburr-chamfering r Primary hobbing time is done in parallel to the load /unload, and roll /press deburr-chamfering, between two cuts – on two work-tables Gear hobbing machine LC 180 Chamfer Cut r High chamfer quality with one-cut hobbing strategy r Primary hobbing time is done in parallel to chamfering in a second machining position Generating grinding machine LGG 180 / LGG 280 r A single-table solution for gear grinding of workpieces up to Ø 180 mm, or up to Ø 280 mm, and workpiece lengths up to 500 mm r Extremely fast load/unload times of 4 seconds, chip-to-chip, with a single-table r New Palletizer LPS 3400 Generating grinding machine LGG 180 / LGG 280 r A single-table solution for gear grinding of workpieces up to Ø 180 mm, or up to Ø 280 mm, and workpiece lengths up to 500 mm r Extremely fast load/unload times of 4 seconds, chip-to-chip, with a single-table r New Palletizer LPS 3400 Gear hobbing machine LCH 180 two r Multi-cut strategy with roll /press deburr-chamfering r Primary hobbing time is done in parallel to the load /unload, and roll /press deburr-chamfering, between two cuts – on two work-tables Liebherr Gear Technology, Inc. 1465 Woodland Drive Saline, Michigan 48176-1259 Phone.: +1 734 429 72 25 E-mail: info.lgt@liebherr.com www.liebherr.com The Group Visit us at Booth N-6930 September 8-13, 2014 %VSJOHEFWFMPQNFOUPGPVSJOOPWBUJPOT XFQMBDFQBSUJDVMBS FNQIBTJTPODIPPTJOHBOPQUJNBMTPMVUJPOGPSUIFSFTQFDUJWF BQQMJDBUJPO5IFSFTVMU1SPDFTTTUBCJMJUZBOEBOPVUTUBOEJOH RVBMJUZPGNBOVGBDUVSFEDPNQPOFOUToXJUIUIF IJHIFTUMFWFM PGFDPOPNZQPTTJCMF ,0# 3400 0314 Liebherr.indd 1 2/7/14 10:09 AM