Gear Production

Issue link: http://gear.epubxp.com/i/262216

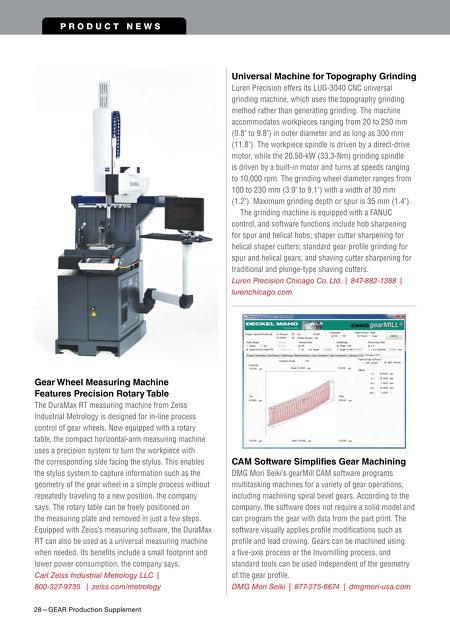

28—GEAR Production Supplement P r o d u c t N e w s CAM Software Simplifes Gear Machining DMG Mori Seiki's gearMill CAM software programs multitasking machines for a variety of gear operations, including machining spiral bevel gears. According to the company, the software does not require a solid model and can program the gear with data from the part print. The software visually applies profle modifcations such as profle and lead crowing. Gears can be machined using a fve-axis process or the Invomilling process, and standard tools can be used independent of the geometry of the gear profle. DMG Mori Seiki | 877-275-6674 | dmgmori-usa.com Gear Wheel Measuring Machine Features Precision Rotary Table The DuraMax RT measuring machine from Zeiss Industrial Metrology is designed for in-line process control of gear wheels. Now equipped with a rotary table, the compact horizontal-arm measuring machine uses a precision system to turn the workpiece with the corresponding side facing the stylus. This enables the stylus system to capture information such as the geometry of the gear wheel in a simple process without repeatedly traveling to a new position, the company says. The rotary table can be freely positioned on the measuring plate and removed in just a few steps. Equipped with Zeiss's measuring software, the DuraMax RT can also be used as a universal measuring machine when needed. Its benefts include a small footprint and lower power consumption, the company says. Carl Zeiss Industrial Metrology LLC | 800-327-9735 | zeiss.com/metrology Universal Machine for Topography Grinding Luren Precision offers its LUG-3040 CNC universal grinding machine, which uses the topography grinding method rather than generating grinding. The machine accommodates workpieces ranging from 20 to 250 mm (0.8" to 9.8") in outer diameter and as long as 300 mm (11.8"). The workpiece spindle is driven by a direct-drive motor, while the 20.50-kW (33.3-Nm) grinding spindle is driven by a built-in motor and turns at speeds ranging to 10,000 rpm. The grinding wheel diameter ranges from 100 to 230 mm (3.9" to 9.1") with a width of 30 mm (1.2"). Maximum grinding depth or spur is 35 mm (1.4"). The grinding machine is equipped with a FANUC control, and software functions include hob sharpening for spur and helical hobs; shaper cutter sharpening for helical shaper cutters; standard gear profle grinding for spur and helical gears; and shaving cutter sharpening for traditional and plunge-type shaving cutters. Luren Precision Chicago Co. Ltd. | 847-882-1388 | lurenchicago.com 0314_MMS_Gear_Products.indd 28 2/14/2014 9:08:11 AM